Explain the Different Types of Production Process With Example

Six types of manufacturing processes Job shop manufacturing. The different types of manufacturing processes under machining are- MIlling Milling is a process of removal of material from a workpiece using.

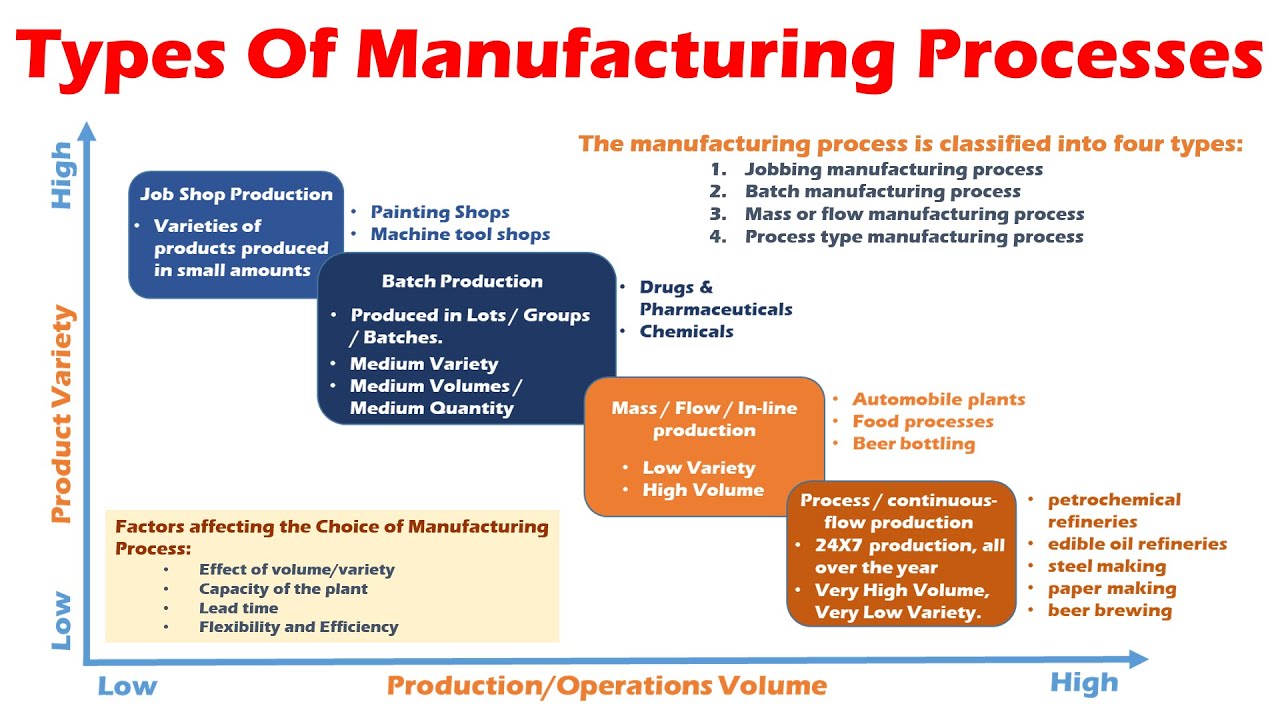

Types Of Manufacturing Processes Job Shop Batch Mass Flow Process Type Manufacturing Processes Youtube

A Continuous Production System.

. Job shop manufacturing uses production areas instead of an assembly line and is most often used. Five types of manufacturing processes. This requires advanced technology that orchestrates a unique process for each item.

A manufacturer uses process types like repetitive manufacturing for repeating production to commit to a production rate. For example a production line that produces shirts that are each different based on customer measurements and preferences. There are mainly two main production systems.

If the products youre creating start out as liquid chances are the manufacturer uses molding. Another thing that distinguishes discrete manufacturing from process manufacturing is the fact that in discrete manufacturing parts in a product can still be distinguished from one another and products can be disassembled broken back down to. Examples of process manufacturing.

Here the production of items takes place in lots or batches. The following are examples of project- or job-based production. The four main types of manufacturing are casting and molding machining joining and shearing and forming.

Broadly there are five manufacturing processes and most businesses that create products will fall into one of these five categories. For example capital and labor can be used as a substitute of each other but to a limited extent only. In general there are three types of production.

Examples of batch production flows include manufacturing of drugs and pharmaceuticals medium and heavy machineries etc. 1 how inputs are converted into outputs and 2 the timing of the process. If your brand plans to produce complex products such as kitchen appliances or furniture youll most likely deal with flow production methods somewhere in your products production process.

Examples of process manufacturing products are. In batch production the product goes through each stage of the process together before moving on to the next stage. Factors of Production Examples.

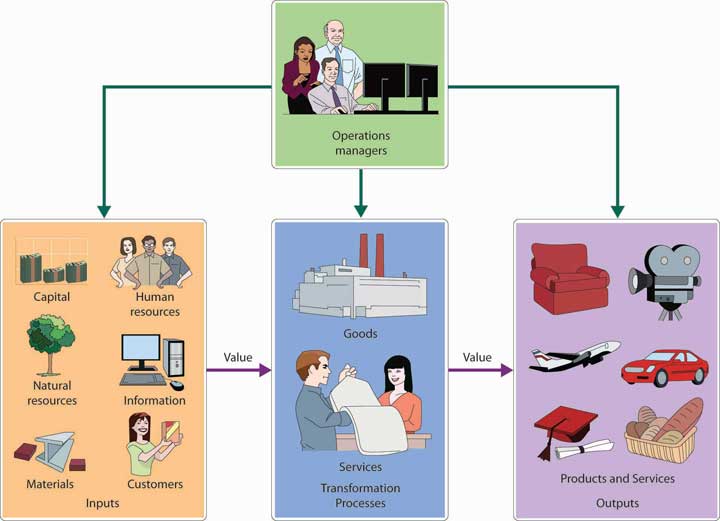

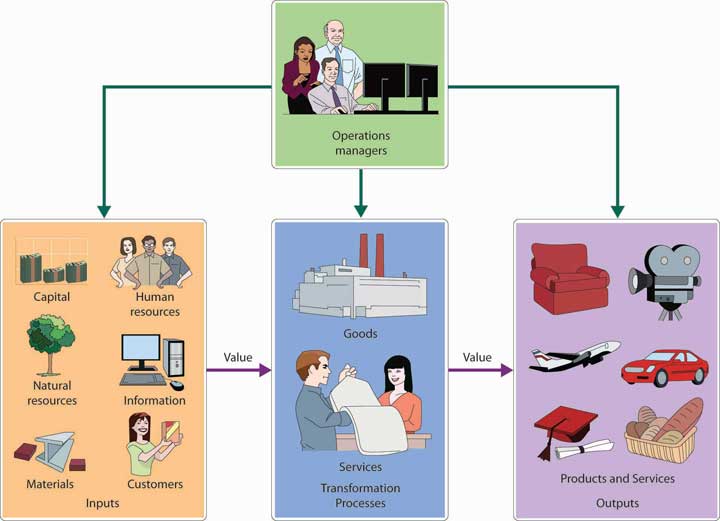

Types of Production Systems Chart Continuous and Intermittent Continuous System or Flow System. In addition to production type operations managers also classify production processes in two ways. The below-mentioned factors of production examples explain the concept even better.

Personal care and cosmetics. TYPES OF MANUFACTURING PROCESS. Here are explain Types of Production Systems.

Flow production involves passing of sub-assemblies or individual parts from one production to the next until the final product is completed. Mass production mass customization and customization. 1 Continuous System and 2 Intermittent System.

There are two main types of production systems. Cobb-Douglas production function refers to the production function in which one input can be substituted by other but to a limited extent. Drinks cereals gasoline concrete etc.

The different types of production function as shown in Figure-16. This way production lines for each stage of the. Production Function with Two Variable Inputs.

Generally used for high-volume low-variety products with standardized parts. Types of Production System. To understand a production function with two variable inputs it is necessary to explain what an isoquant is.

Some of the top process manufacturing markets include. A mass production line that produces unique items to customer specifications. A product is divided into different jobs.

All jobs of one batch of production must be completed before starting the next batch of production. Cobb-Douglas production function can. So let us have a look at them.

Repetitive manufacturing is appropriate when making repeat production at a committed. Assembly process A production process in which the basic inputs are either combined to create the output or transformed into the output. The production function is a short-run production function because it illustrates what happens to output as more and more units of the variable input labour are added to the fixed stock of capital.

Continuous System and Intermittent System with their advantage and disadvantage. An isoquant is also known as iso-product curve or equal-product curve or a production-indifference curve. Continuous process A production process that uses long production runs lasting days weeks or months without equipment shutdowns.

Batch production is a method used to produce similar items in groups stage by stage. A manufacturing process uses manufacturing methods operations scheduling software machinery and labor to transform raw material into the finished product. However how that works for each business will differ slightly based on their.

His father suggested Ryan starting orange juice production on the land on a small scale and see how it goes. Ryan has an ancestral farm where his forefathers used to grow oranges. Process Production System B Intermittent Production System.

132 is a graphic representation of equation 2 which is the short-run production function for radios. Beer brewing is one example of process manufacturing in the food and beverage industry.

11 1 Operations Management In Manufacturing Exploring Business

Garment Manufacturing Process Garment Manufacturing How To Plan Product Development Process

Flowchart Manufacturing Process Process Flow Chart Template Process Flow Chart Flow Chart

Comments

Post a Comment